Reporters: Mr.Konto Pantongkam, Asst.Dr.Pituk Bunnoon, Asst.Dr.Phatchakorn Areekul, Mr.Sutaporn Getpun

Evidence Date: November 6, 2023

Related SDGs:

Related Indicators: 7.4.1, 7.4.3

Details:

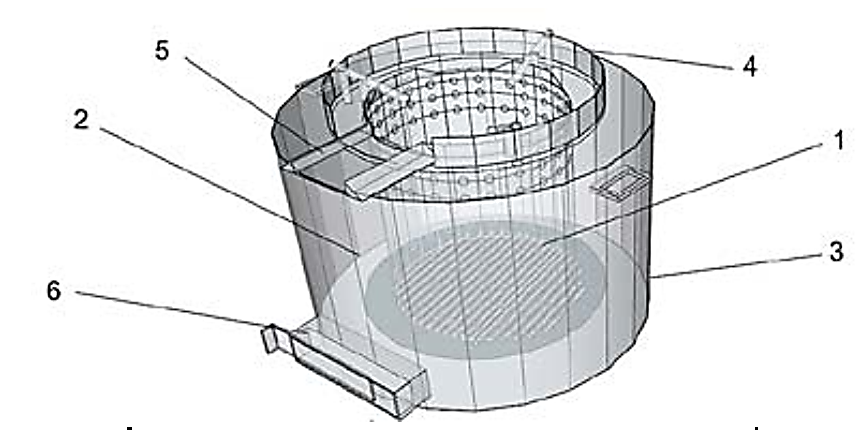

The objective of this research is to develop a TLUD biomass stove and apply it in dyeing pandanus leaves with turmeric. The TLUD biomass stove was constructed using a 200-liter drum as the outer structure. Performance was tested using the Water Boiling Test (WBT). The stove was then used to dye pandanus leaves with natural dye, and the dyed leaves were formed into products. The research found that the TLUD biomass stove from the 200-liter drum had a thermal efficiency (η) of 17.55±0.14%. When dyeing the pandanus leaves with turmeric, the color values before and after dyeing showed a significant difference (p < 0.01). Additionally, dyeing the pandanus leaves with turmeric did not reduce the mechanical properties (tensile strength). When the turmeric-dyed pandanus leaves were used to create bags, the leaves could be woven into products effectively.

Figure 1 shows the structure of the TLUD biomass stove, which consists of: 1) combustion chamber, 2) insulation barrier, 3) stove body, 4) wind shield assembly, 5) fuel feeding inlet, and 6) air control inlet.

- (b)

Figure 2 shows the materials in the area of Khutao District, Bang Klam, Songkhla Province: (a) pandanus leaves and (b) turmeric.

Figure 3 illustrates the application of the TLUD biomass stove for dyeing pandanus leaves using turmeric.

The performance of the TLUD biomass stove, compared to energy-efficient biomass stoves for processing Wunsri’s water chestnut (Wunsri et al., 2021) and energy-efficient biomass stoves for processing clams (Wunsri et al., 2020), was found to have lower thermal efficiency. However, it offers more flexibility in use, as it can accommodate various types of cookware, such as pans, pots, metal basins, and steel drums. Its production cost is lower, it is portable, and the assembly time is short, making it easy to transfer technology and enabling immediate use after assembly.

Figure 7 shows examples of woven products made from pandanus leaves (Toei Nam with Turmeric).

When tested for dyeing pandanus leaves using natural methods with turmeric, it was found that the color from the turmeric could adhere well to the pandanus leaves. The dyeing process did not reduce the mechanical properties (tensile strength), and when the turmeric-dyed pandanus leaves were formed into bags, they could be woven effectively into products. This results in an environmentally friendly natural product that can add value to community products. This research was presented by Supranee Wunsri and her team from Rajamangala University of Technology Srivijaya. Published in the Journal of the Research Unit for Science, Technology, and Environmental Learning, Volume 14, Issue 2 (2023).

Related Links:

https://ejournals.swu.ac.th/index.php/JSTEL/article/view/15393

https://search.tci-thailand.org/article.html?b3BlbkFydGljbGUmaWQ9NzM2NTEz